The process of CNC cutting of Metals and Plastic: Defining a Machine Shop

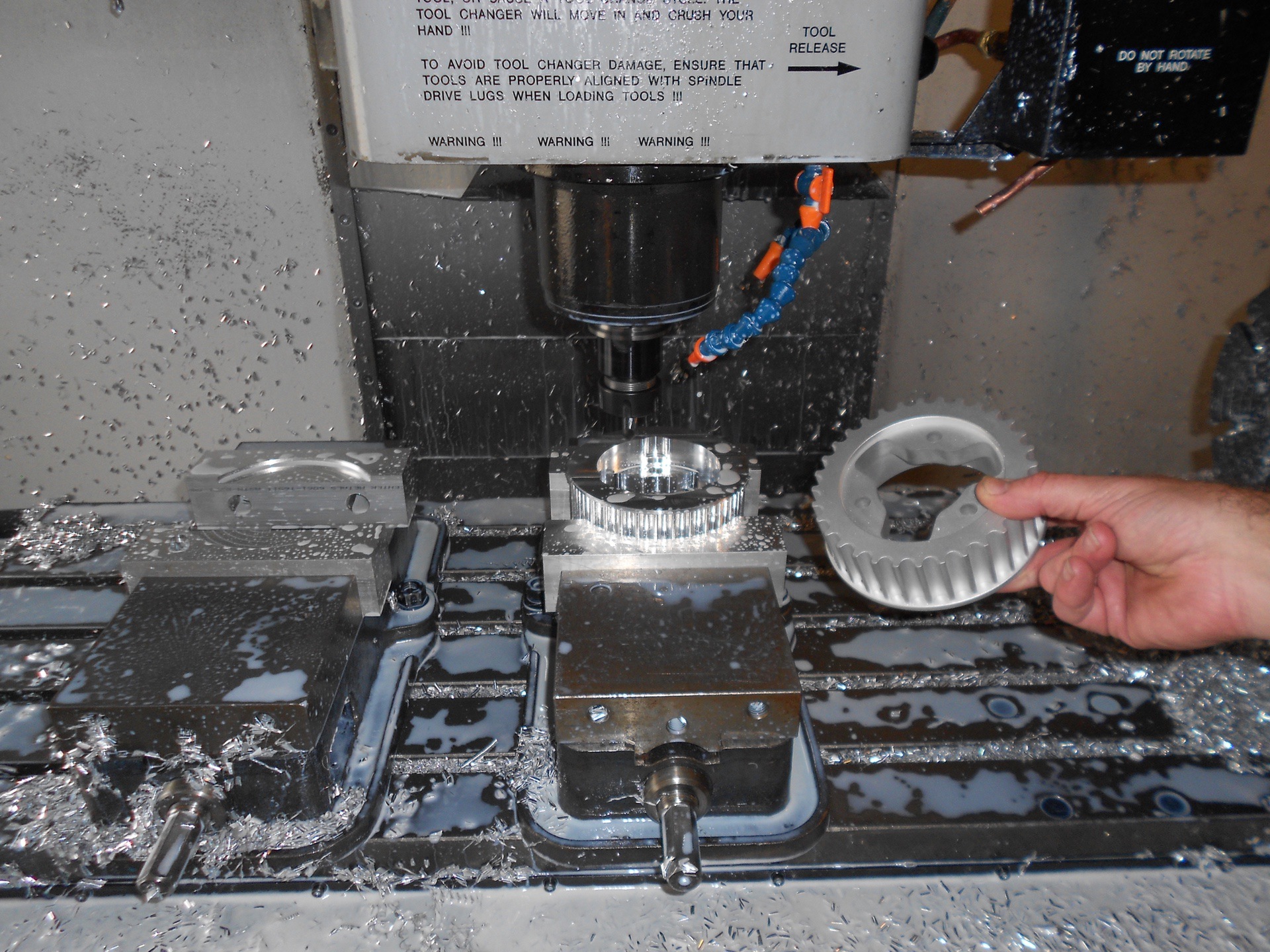

CNC – Computer Numerical Control

Taking digitized data, a computer and CAM program is used to control, automate, and monitor the movements of a machine. The machine can be a milling machine, lathe, router, welder, grinder, laser or waterjet cutter, sheet metal stamping machine, robot, or many other types of machines.

AS 9100D Standard Benefits

AS 9100D Standard Benefits

The aircraft and aerospace industries are quickly embracing AS 9100D as a means of improving quality and on-time delivery within their supply chain. Public demand for safety and reliability drives the need for product quality to approach near perfection. The only way to work towards perfection is to work through continuous improvement. Quality management systems in conjunction with third party audits are integral to continuous improvement.

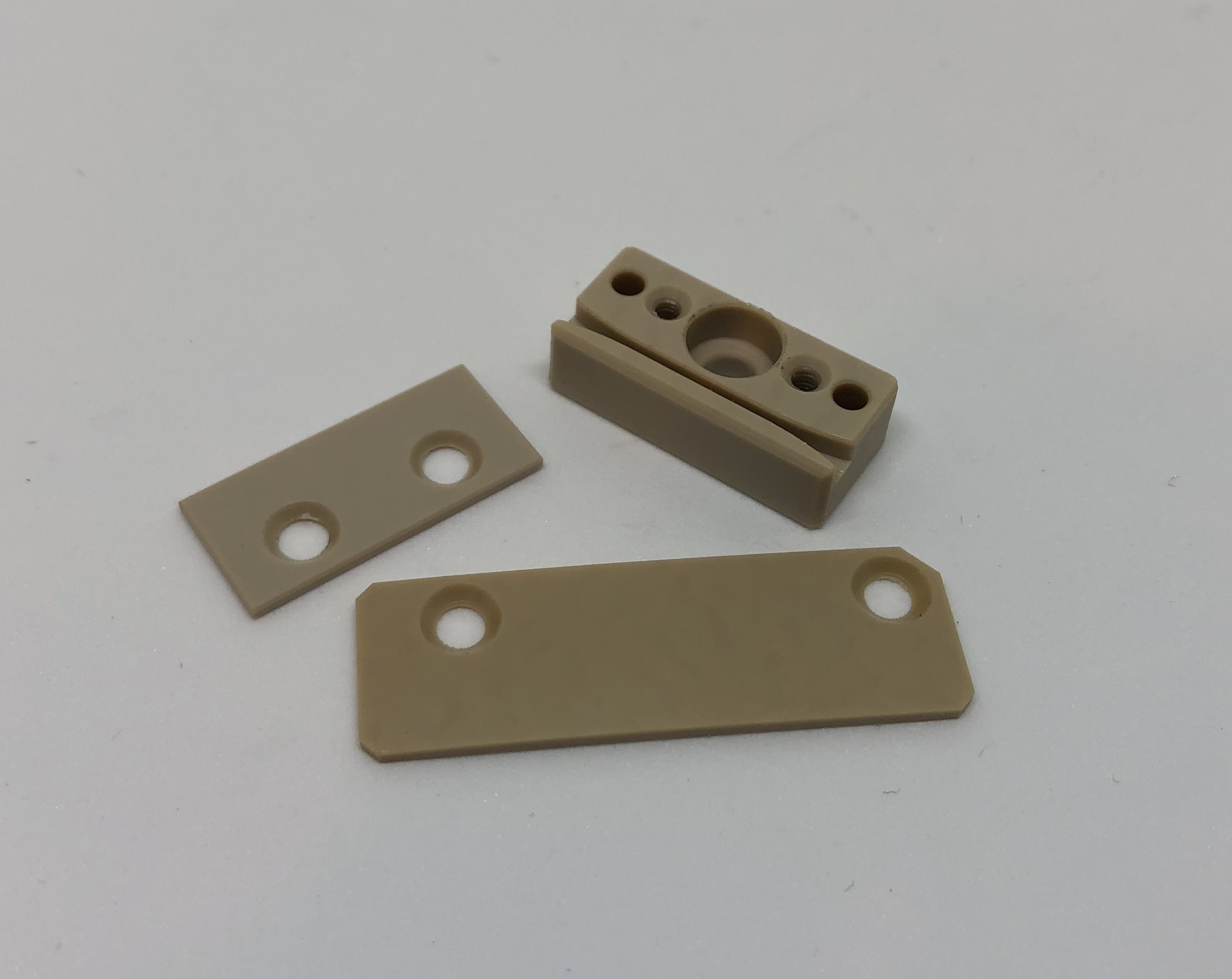

Plastic We Mill & Turn

S3 MFG. has been machining PEEK plastic for twenty years….

PEEK (polyetheretherketone) is a high-performance engineering plastic with outstanding resistance to harsh chemicals, and excellent mechanical strength and dimensional stability. It offers hydrolysis resistance to steam, water, and sea water. PEEK has the ability to maintain stiffness at high temperatures and is suitable for continuous use at temperatures up to 338oF (170oC). This engineering plastic has a proven track record in challenging environments such as aerospace, oil and gas, food and beverage processing, and semiconductor.

Types of Brass Machined

Brass is an alloy of copper and zinc, in proportions which can be varied to achieve varying mechanical and electrical properties. From simple threaded inserts, to complex manifolds, S3 Manufacturing can work with any print to create a custom, high quality, made in America brass part! We can source the material, Machine the part, install inserts and even place the component into a sub assembly shipping to anywhere in the world, S3 MFG can do it all!

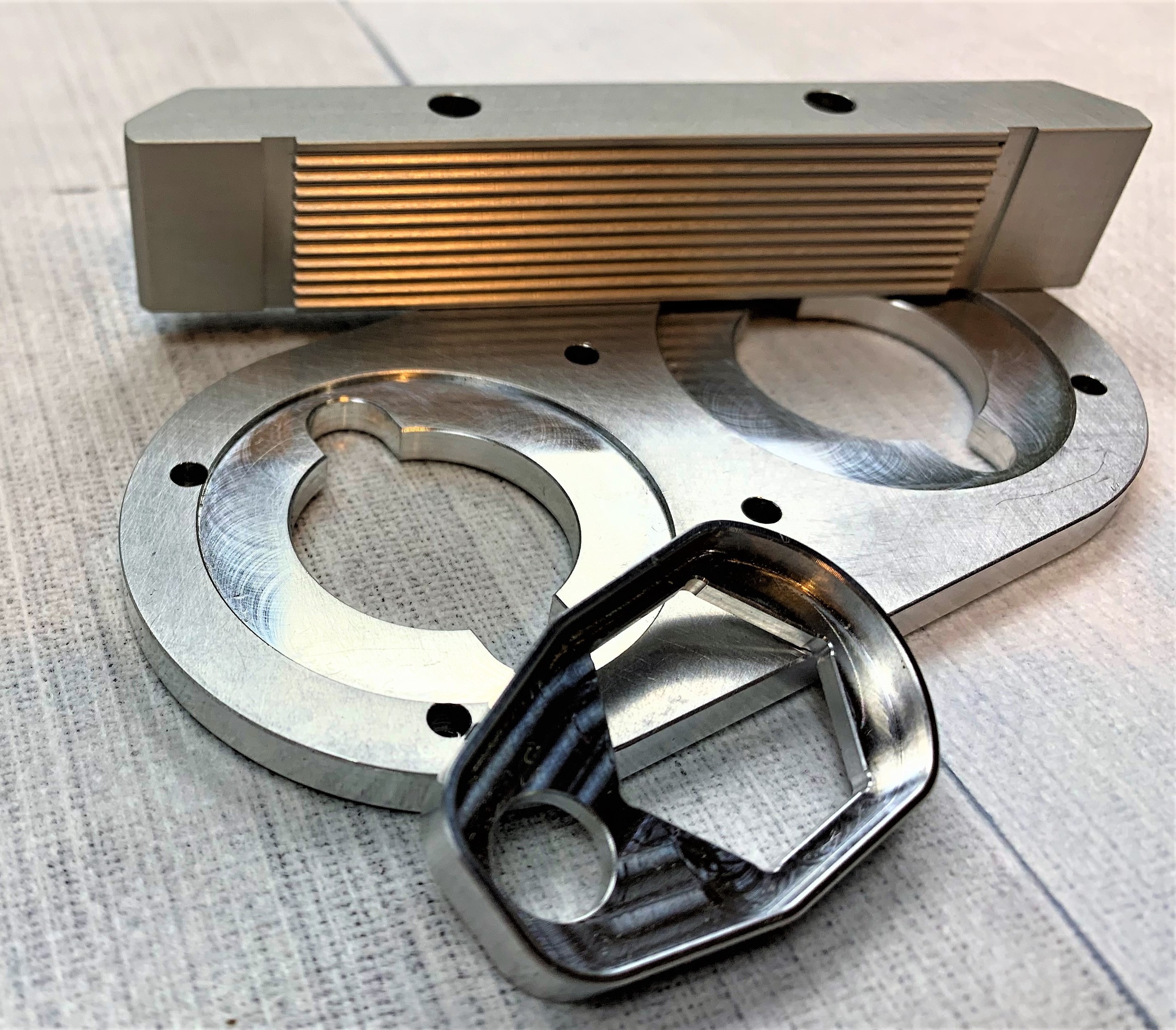

Aluminum Grades Machined

Light, durable and functional: These are the qualities that make aluminum one of the key engineering materials of our time. Due to its lighter material weight, lower material hardness, and greater form-ability, aluminum is ideal for use in machining and other manufacturing operations.

S3 has capability of machining any shape and size of this versatile material as well as Anodizing. Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. Aluminum is ideally suited to anodizing, although other nonferrous metals, such as magnesium and titanium, also can be anodized.

Steel Grades Machined

Steel is an alloy of iron with typically a few tenths of a percent of carbon to improve its strength and fracture resistance compared to iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant need typically an additional 11% chromium.

Mild Steel

Mild steel is a type of carbon steel with a low amount of carbon – it is actually also known as “low carbon steel.” Although ranges vary depending on the source, the amount of carbon typically found in mild steel is 0.05% to 0.25% by weight, whereas higher carbon steels are typically described as having a carbon …

From Mild Steel to Carbon Steel and every type of stainless steel, we can mill it and turn it!

S3 Manufacturing’s Capabilities

S3’s manufacturing expertise and experience is extensive and includes multi-pallet, robotic systems, horizontal milling, vertical milling, turning with live tooling, multi-axis machining and process automation including supporting processes for precision welding and assembly.